MATHIASEN

MACHINERY, INC.

MATHIASEN

MACHINERY, INC.

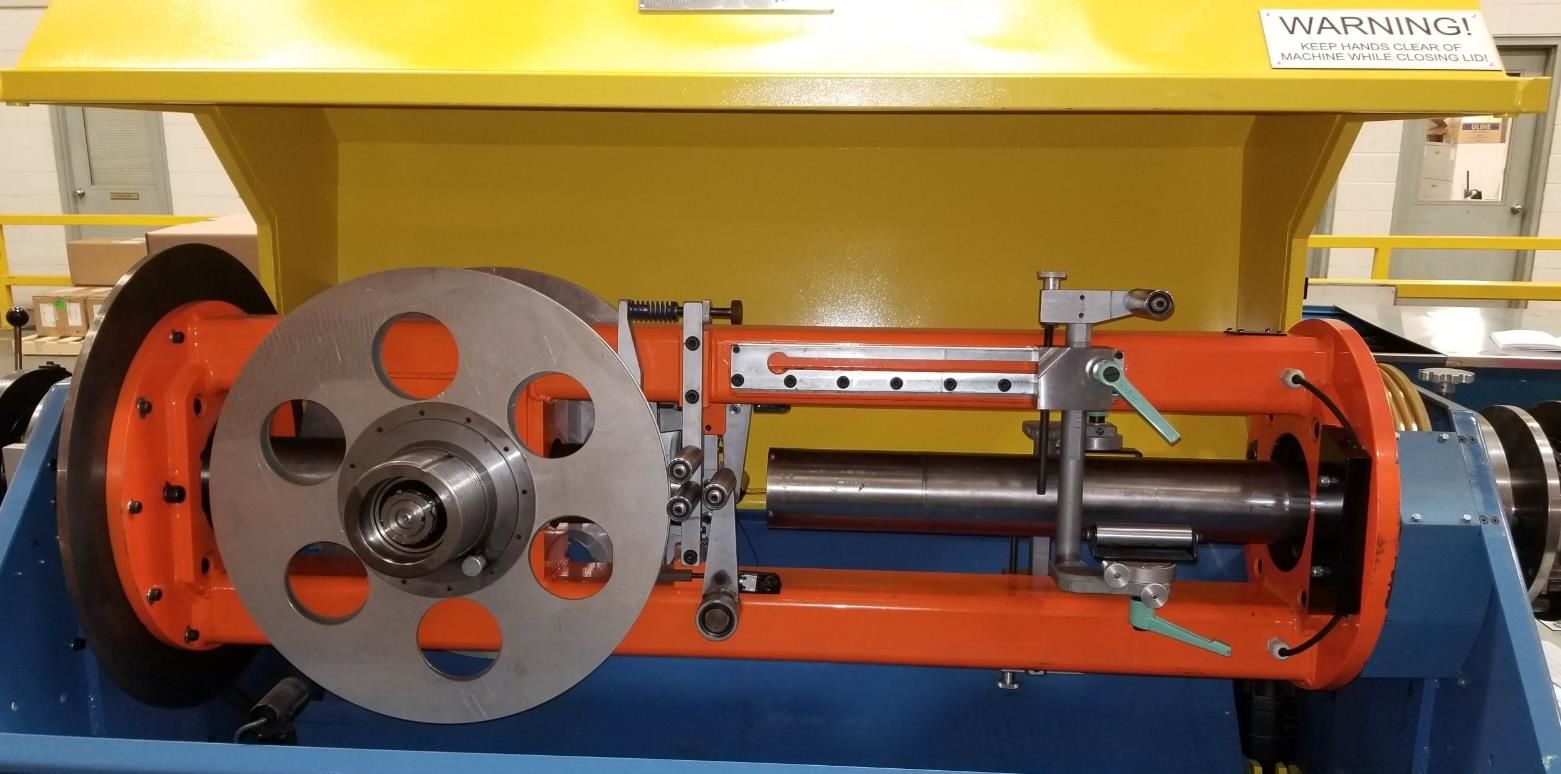

Ref. #46-124Dual Eccentric Taping Machine

Mfg: Kalmark

Year of Mfg. 2018 (never used)

Model: ETH-2x610-15.0

Maximum speed; 800 RPM

Noise Level 80 dBA measured at pre-commission

Tape Tension; 2 - 10 Kg

Tape width; 12.7 - 100 mm

Tape overall diameter; 610 mm OD maximum.

Tape bore; 2 x 152 mm diameter

Tape materials; Metallic/ Non-Metallic

Tape thickness; 0.05 - 0.5 mm

Lay angle; 75 - 28 degrees

Tape overlap; 0% - 50%

Cable diameter; 10 - 90 mm (0.4” - 3.5”)

Machine bore of passage; 100 mm (4”)

15 HP AC motor drive and controller. 480V/3PH/60Hz

Features:

Suitable for the application of thin metallic and non-metallic tapes including: Non-metallic; oriented polypropylene woven cloth, polyester fiber glass reinforced, paper, and Mylar tapes. Metallic; thin copper, bronze or stainless steel.

Constant tension dancer assemblies for uniform and consistent tape application, manually adjustable tension.

Broken tape and low pad sensors.

All guide roller assemblies on mechanical actuated assemblies with scales.

Electrically interlocked machine enclosure.

Large LEXAN viewing window of tape application point.

Guide roller assemblies at entrance and exit of the machine.

Removable split closing die at point of tape application.

Machine is driven by an independent 15.0 HP MATRATHON Black Max AC vector duty motor. Motor drive controller is EMERSON M7 Control Techniques.

Tape overlap / lay is via numeric keypad ratio unit of drive HMI.

Machine data access unit provides operator information such as; BROKEN TAPE, LOW PAD, COVER OPEN, EMERGENCY STOP, TAPE LAY, and TAPE HEAD RPM.